Creo Complete Machining, Power to Drive Virtually Any Type of NC Machine

Download a 30-day Trial of Creo 7.0!

By form submission, you agree to the Terms of Service

ABOUT

Complete Machining:

Powerful, Comprehensive Package of NC Programming Capabilities!

Creo Complete Machining allows you to work concurrently with designers to automatically incorporate design changes. With integrated collaboration between two fundamental areas of development, you have the power to increase product quality, reduce scrap, and decrease production time and costs.

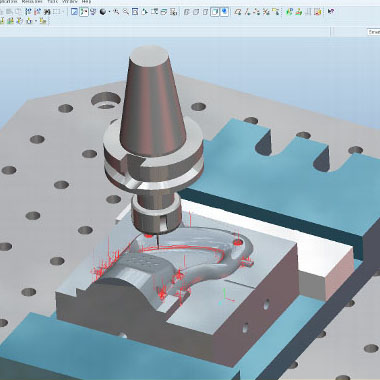

Create NC toolpaths faster using graphical dynamic toolpath display, which allows you to visualize the resulting toolpath even when is under definition, and leverage a powerful process manager with easy-to-use dashboard controls.

PTC Creo Complete Machining gives you the broadest range of capabilities to meet all your production machining needs. Put Creo Complete Machining to work for you.

-

EXTEND CAPABILITIES

EXTEND CAPABILITIES

Extends the full associativity of PTC Creo Parametric™ capabilities into manufacturing, and eliminates the inaccuracies and inconvenience of exporting PTC Creo Parametric geometry to third-party machining software.

-

DATA MANAGEMENT

DATA MANAGEMENT

Improve manufacturing set-up and quality control processes with in-process probing support. Provide robust data management of manufacturing models and deliverables with PTC Windchill® PDMLink® and PTC Windchill MPMLink® (optionally available)

-

WELL DOCUMENTED

Features

Creo Complete Machining - Achieve Concurrent Engineering

Images & Videos

Design Examples Using Creo Complete Machining

Select Category

-

Wire EDM

Wire EDM2-axis contouring with advanced conics and support for multiple rough and skim cuts.

-

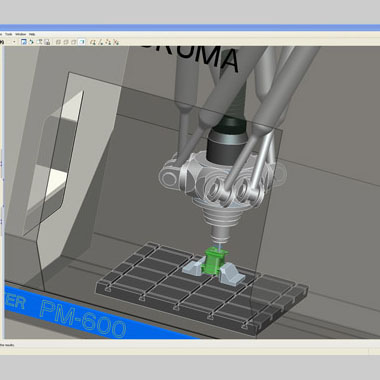

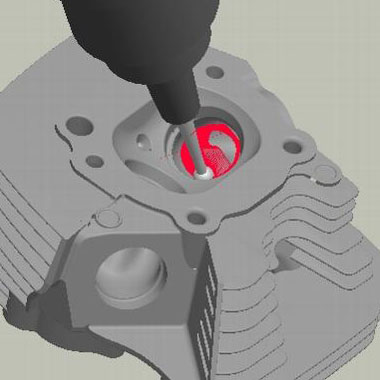

Integrated NC Simulation

Integrated NC SimulationMachine kinematics simulation and collision detection, with automatic error detection.

-

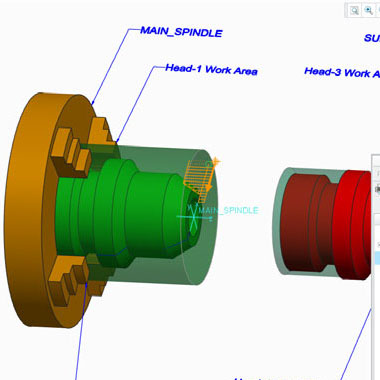

Turning

TurningAutomatic update of in-process workpiece with dual turret 4-axis synchronization.

-

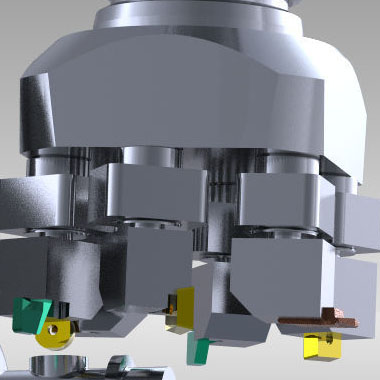

Multi-Task Machining

Multi-Task MachiningExpanded capabilities to support up to 4 heads and 2 Spindles (main and sub-spindle).

-

Multi-Axis Milling

Multi-Axis MillingMulti-surface, 5-axis machining: conventional, isolines and cutlines.

-

-

-

-

-

See More Videos on Creo Products